[pexnivoslider pex_attr_sliderid=”120″][/pexnivoslider]

Project Background

The Town of Newport, Indiana was the last County Seat in the State of Indiana that remained unsewered. Documented issues with Escherichia coli (E. coli) in open waterways resulted in the County Sanitarian requiring the Town to address this threat to the health of their community and the environment.

A new treatment plant and collection system can be a costly endeavor for a small town. In addition, an open-cut gravity sewer system can be extremely difficult to install without damaging the existing infrastructure and historic areas. Some engineering firms suggested the use of Lagoons, but Commonwealth understood that after only 5 years of operation, upon the renewal of their NPDES permit, IDEM would establish an acute ammonia requirement that would not be met with a Lagoon System.

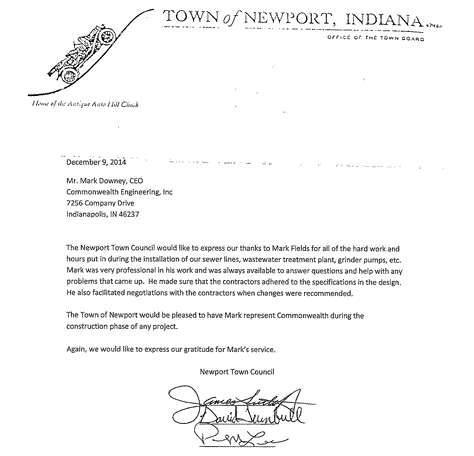

Commonwealth Engineers’ expertise in technology, as well as regulations and funding, helped the Town of Newport to become the first project in the State of Indiana to obtain grants from all three funding agencies, SRF, USDA, and OCRA, and achieve 75% of project costs in grants and 25% in loans. Furthermore, the quality of the design and close construction monitoring resulted in the construction phase of the project being completed under budget with a remaining construction contingency of upwards of $450,000. All construction contingencies were able to be conserved with minimal change orders during construction (the industry standard is typically 3-4% above bid costs). The contingencies afforded the Town to utilize the additional funds for wastewater-related needs for their new utility such as vehicles, tools, equipment, and more.

Project Highlights:

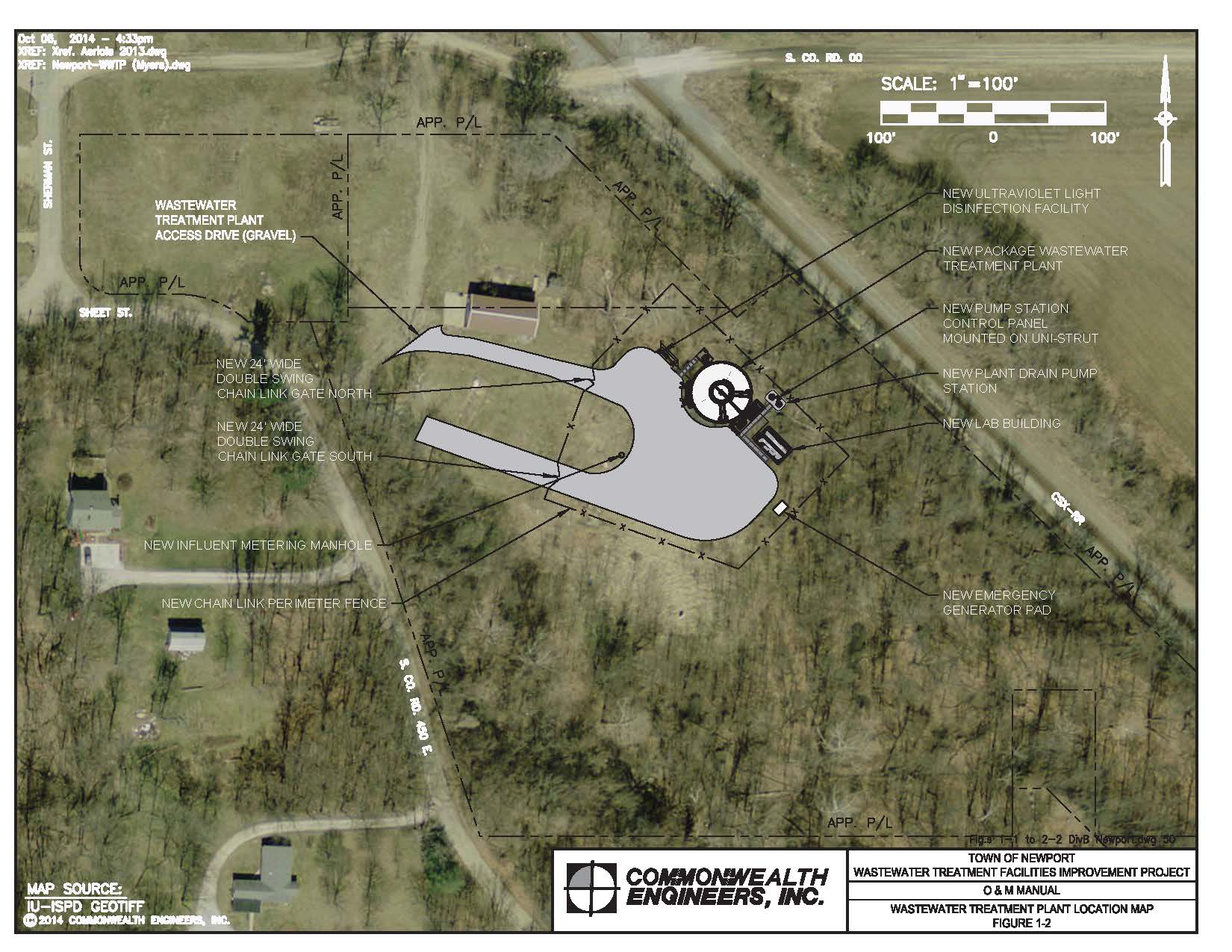

The New Wastewater Treatment and Collection System project included providing a new wastewater utility for the unsewered Town of Newport. The sanitary collection system consists of low pressure sewers with approximately 207 grinder pump stations. The treatment system consists of a mechanical extended aeration treatment plant, ultraviolet disinfection, plant out fall structure, lab building, and all required ancillary equipment. The proposed collection system consists of 26,000 lineal feet of pressure sewer main installed via directional drilling methods to minimize land disturbance and subsequent surface restoration. The average daily design flow to the plant is 0.047 MGD and the peak design flow is 0.149 MGD.

- New wastewater utility and improved environmental quality for Town and nearby waterways with minimal construction impact to the community.

- Improved economic viability for the Town (the Vermillion County Seat).

- Various funding, making project affordable: RD Grant $3,450,000; RD Loan $1,375,000; SRF Loan Forgiveness $600,000; OCRA Grant $500,000.

- Quality of design, close construction monitoring, and minimal change orders resulted in all construction contingencies being preserved which allowed the Town to purchase additional equipment for their new wastewater utility including these major items: Backhoe, ATV, Vacuum Truck, Utility Service Vehicle, and more.

Grinder Pump Installation:

For More Information: