Wastewater Improvements Project

Town of Osgood, Indiana

Project Background

The Town of Osgood, Indiana, built a wastewater treatment plant in 1997, but there were issues that were not addressed with the original design. High Inflow & Infiltration in the sanitary sewer system resulted in high flows that required the reporting of non-compliance to IDEM. The performance of the wastewater treatment plant was also compromised due to high wet weather flows and, in some instances, Ammonia, TSS, and BOD effluent limitation violations occurred.

The Council knew they had to address future growth to the utility, aging equipment, and compliance issues while still meeting the needs of the community without a negative economic impact. Commonwealth Engineers developed plans for the upgrade of the Utility and assisted the Town of Osgood with securing federal, state, and regional grant funds that minimized the need to raise rates for residents.

Project Highlights

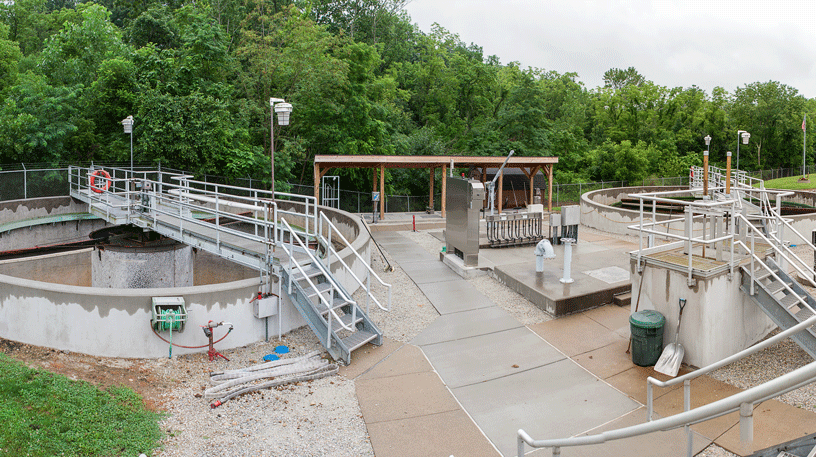

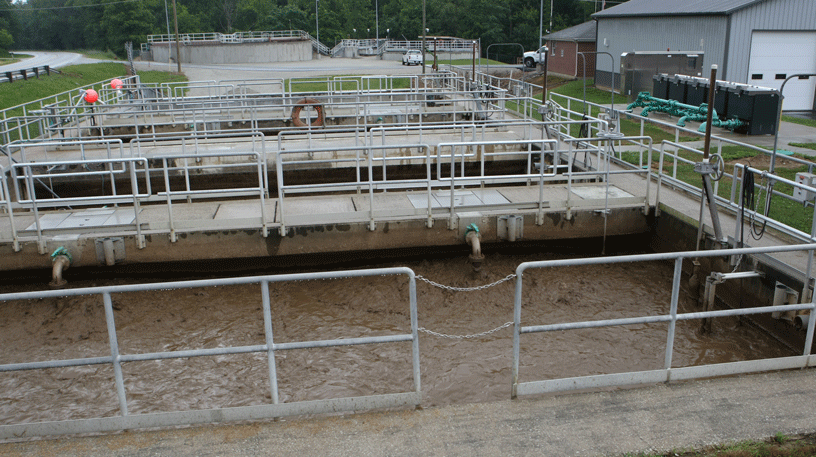

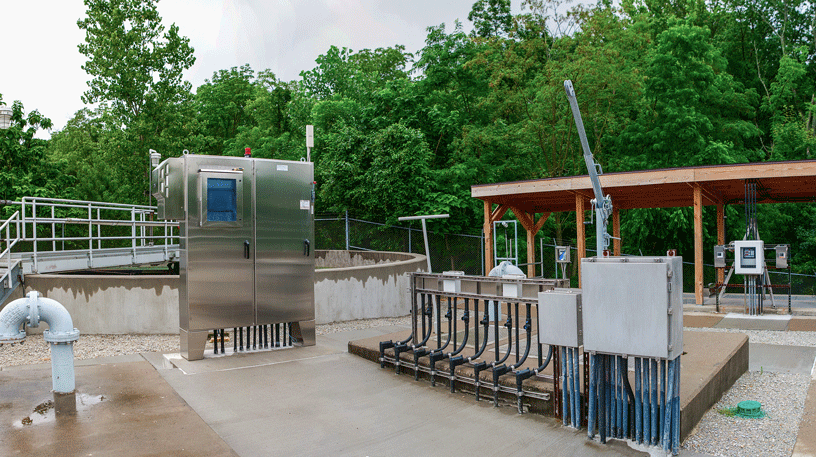

The project consisted of wastewater collection system rehabilitation and wastewater treatment plant (WWTP) improvements directed toward increasing operational efficiency and increasing peak wet weather flow rate capability by providing offline flow equalization.

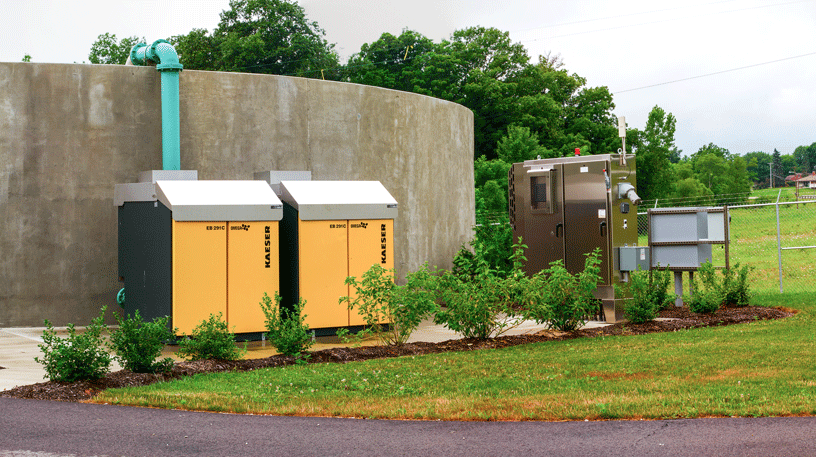

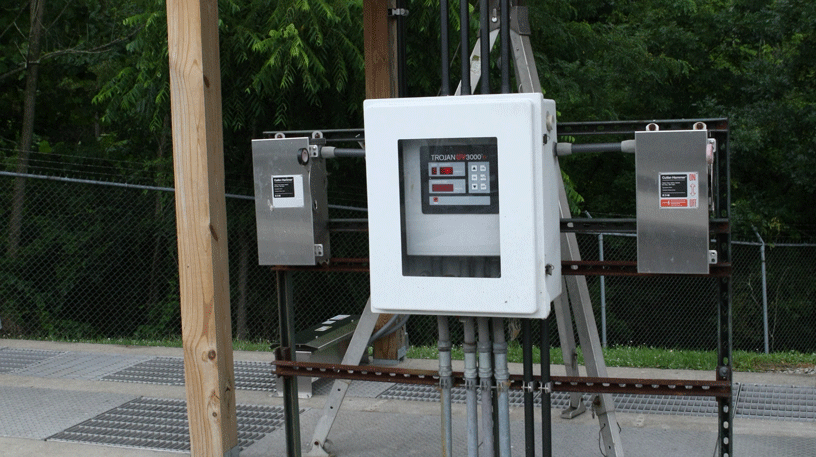

Baffle walls were constructed in the Influent and RAS/WAS wet wells to correct poor hydraulic conditions and extend pump life. Energy efficiency improvements included VFD-controlled influent pumps and RAS/WAS pumps, VFD-controlled oxidation ditch rotors based on oxygen concentration, and separate blowers for each digester with VFD control again based on oxygen concentration. A new septage receiving station was constructed to accept material from the Town’s sewer cleaning truck. A sludge bagging station was constructed as a secondary means of sludge disposal whenever the land application isn’t feasible. Digester concrete repair was performed to extend service life. A new SCADA system was installed to control all the new energy-efficient equipment. Weather station equipment was installed at the WWTP and incorporated into the SCADA and alarming systems affording operations staff efficient and accurate indicators to prepare for and address wet weather events. Other improvements include a UV unit roof, outfall observation platform, influent screen repairs, polymer feed system, replacement tank sensors, flow meters, electric access gate, and drive paving. Additional electrical, mechanical, and site work was performed in order to support the improvements listed above.

The sewer system rehabilitation work consisted of manhole rehabilitation using cementitious lining and pipeline rehabilitation using a cured-in-place pipe liner.

Major Project Components

- 0.5 MG Equalization Tank

- Influent & RAS/WAS Pumps

- Digester & EQ Blowers

- VFD Controlled Oxidation Ditch Rotors

- Septage Receiving Facility

- Polymer Feed System

- Sludge Bagging System

- SCADA System

- Digester Concrete Repair